Overview

ModAE’s Asset Health Management (AHM) solutions provide industry-leading tools for maintaining the reliability, availability and performance of critical machinery across energy sectors. By combining real-time data acquisition, advanced analytics, and intuitive visualization, these systems deliver a complete overview of equipment health, ensuring timely intervention and minimizing unplanned outages.

Key Features

- Real-Time Monitoring

Our AHM solutions continuously track key parameters such as vibration, temperature, positions, Speed and process parameters customized for specific applications, enabling immediate detection of abnormal conditions. This real-time data stream allows maintenance teams to respond proactively, preventing minor issues from escalating into major breakdowns. - Enhanced Connectivity

Integrated systems offer seamless connectivity between asset health monitoring and maintenance execution, ensuring data flows efficiently across the organization. This connectivity supports better resource allocation, coordinated maintenance efforts, and faster response times. - Advanced Analytics

Leveraging cutting-edge analytics, our AHM systems transform raw data into actionable insights. By combining historical trends, root cause analysis, related inputs and predictive algorithms, we help clients make informed decisions about asset performance and maintenance planning. - Visualizations and Reporting

Our solutions offer clear visual representations of asset conditions, including dashboards, trend charts, and custom reports. These visual tools help prioritize maintenance actions, allocate resources effectively, and provide comprehensive overviews of asset health for stakeholders. - Scalable Solutions

From single machines to plant-wide coverage, ModAE’s AHM systems are designed to scale. Whether it’s a standalone unit or an enterprise-level solution, our systems grow with operational needs, ensuring continuous support as asset portfolios expand.

Applications

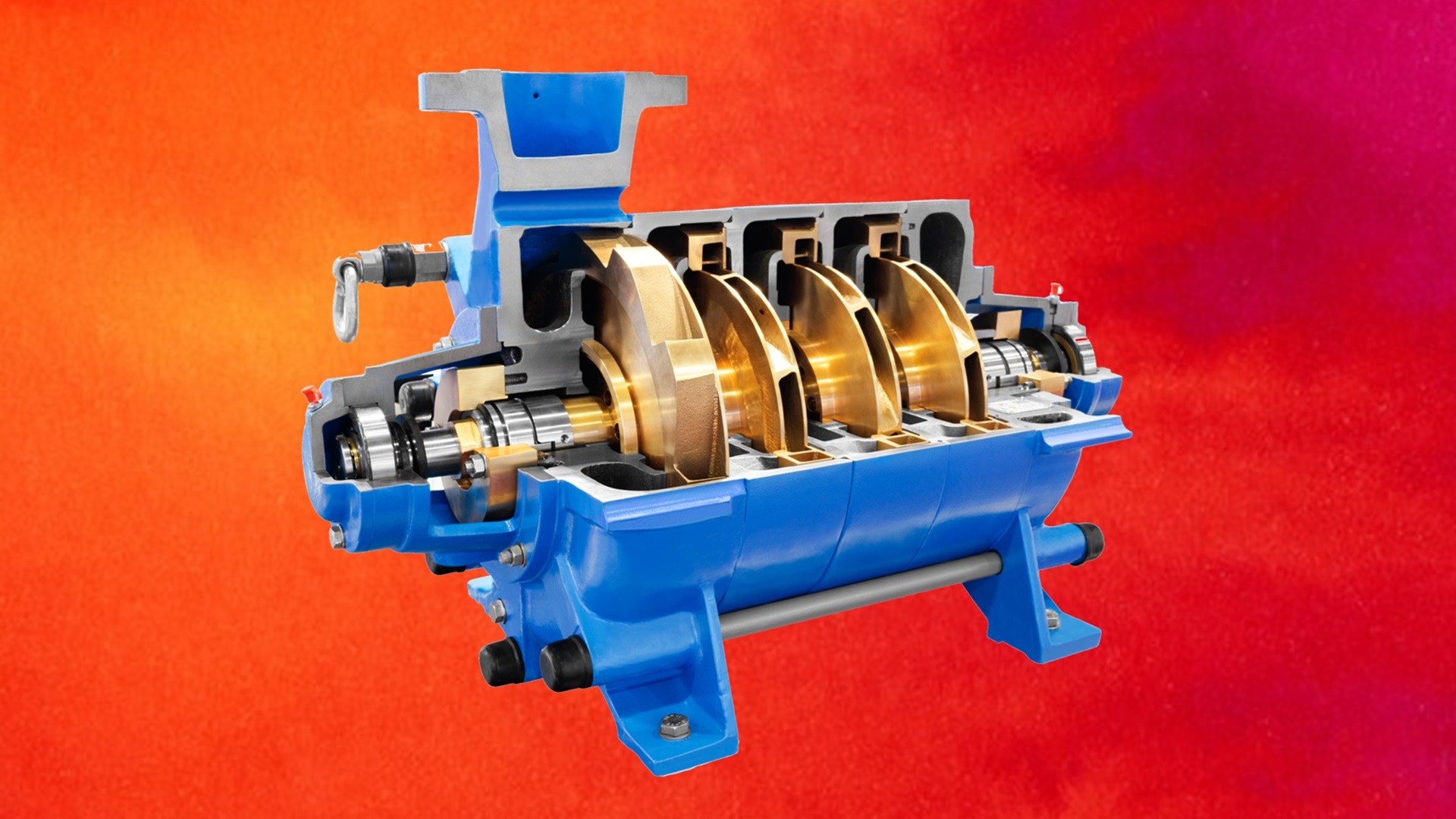

ModAE’s Asset Health Management solutions are ideal for power plants, oil & gas facilities, and petrochemical industries. They are used to track the condition of rotating equipment, turbines, pumps, and compressors, in general catering to rotating and reciprocating machines and providing a unified platform for maintaining optimal performance and extending asset lifespans.

Benefits

- Increases operational efficiency by reducing unplanned outages and optimizing maintenance schedules.

- Minimizes maintenance costs by identifying and resolving issues before they impact performance.

- Extends asset life and maximizes uptime by providing continuous oversight and early warnings.

- Enhances safety and compliance by ensuring equipment operates within prescribed parameters.

- Supports enterprise-wide visibility, offering a unified view of all critical assets.

Related Services

- Project Engineering and Management: Complete solution right from writing specification, carrying out detailed design and engineering and project management services

- Installation and Commissioning: Complete support for deploying asset health management systems.

- Condition Monitoring and Diagnostics: Advanced diagnostics to assess asset condition and recommend corrective actions.

- Remote Monitoring: Continuous monitoring from remote locations for enhanced safety and efficiency.

- Training and Skill Development: Training programs for maintenance teams on effective AHM system utilization.

Frequently Asked Questions

ModAE’s AHM solutions provide comprehensive tools for monitoring the health and performance of critical machinery. By using real-time data, advanced analytics, and visual dashboards, they help identify potential issues early, enabling proactive maintenance and reducing unplanned outages.

Real-time monitoring tracks critical parameters like vibration, temperature, and speed continuously, allowing immediate detection of anomalies. This proactive approach helps maintenance teams respond quickly to prevent minor issues from escalating into major equipment breakdowns.

ModAE’s AHM solutions are ideal for industries like power generation, oil & gas, and petrochemicals. They are specifically designed to monitor rotating and reciprocating machinery such as turbines, pumps, and compressors, ensuring optimal performance and safety.

ModAE’s AHM solutions provide seamless integration between asset monitoring and maintenance systems, ensuring efficient data flow. This connectivity supports better resource allocation, coordinated maintenance efforts, and faster response times across the organization.

ModAE offers a range of related services including project engineering, installation and commissioning, condition monitoring and diagnostics, remote monitoring, and specialized training to support effective utilization and management of the AHM systems.