Overview

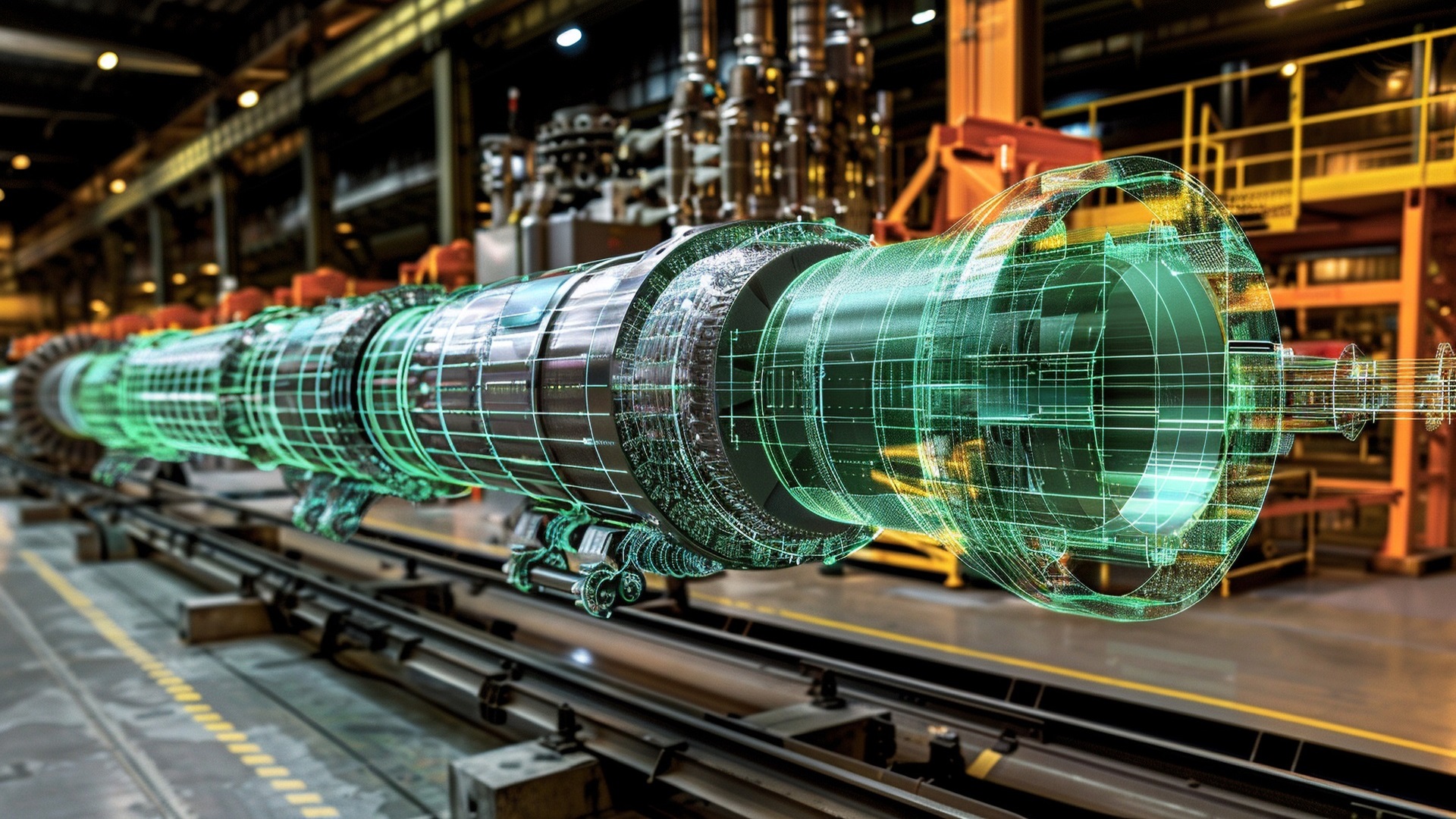

ModAE provides a range of sophisticated monitoring systems designed to ensure the safety, reliability, and performance of critical rotating equipment in energy sectors. These systems offer plant-wide machinery monitoring and comprehensive asset protection, allowing clients to optimize operations and achieve long-term equipment health. With capabilities for real-time data acquisition, early fault detection, and seamless integration, ModAE’s monitoring solutions enable clients to enhance productivity and prevent costly downtimes.

Key Features

- Real-Time Condition Monitoring

Continuously captures essential parameters such as vibration, temperature, and position, enabling round-the-clock visibility of machinery health. Early anomaly detection allows for prompt intervention, minimizing the risk of equipment failure. - Predictive Maintenance Planning

Leverages advanced data analytics to predict potential faults, enabling proactive scheduling of maintenance activities. This reduces unexpected shutdowns and extends machinery lifespan, resulting in higher availability and reduced maintenance costs. - Scalable and Modular Design

Our systems are designed to adapt to both small and large-scale operations. With modular components, clients can start with a basic setup and expand the system as their requirements grow, ensuring that their monitoring system evolves with their business. - Customizable Alarm Management

Configurable alarms and thresholds tailored to various operational conditions help in identifying critical changes in machinery status. This ensures that maintenance teams are alerted in time and can implement corrective actions promptly. - Multi-Channel and Distributed Monitoring

Supports multi-channel monitoring of several machines simultaneously, providing centralized control over machinery health across different units. Distributed systems reduce wiring costs and offer flexibility in remote or complex setups. - Remote Access and Cloud Integration

Offers secure remote access and cloud integration, allowing monitoring and diagnostics to be performed from anywhere. This is particularly beneficial for remote locations or hazardous environments, as it minimizes the need for on-site personnel.

Applications

ModAE’s monitoring systems are essential in power generation facilities (thermal, nuclear, hydro), oil & gas plants, and petrochemical industries. They are widely used for monitoring turbines, compressors, pumps, and other critical rotating equipment to track and ensure operational efficiency and safety.

Benefits

- Prevents unexpected equipment failures by providing continuous data and early warning signals.

- Enhances plant safety by identifying abnormal conditions before they escalate.

- Reduces maintenance costs by enabling condition-based maintenance planning.

- Extends machinery life through comprehensive asset health management.

- Supports high asset availability, ensuring maximum productivity.

Related Services

- Installation and Commissioning: Expertise in setting up monitoring systems for optimal performance.

- Lifecycle Support: Ongoing maintenance, upgrades, and calibration to maintain system reliability.

- Remote Monitoring: Real-time condition monitoring using cloud-based platforms.

- Diagnostics and Troubleshooting: Data-driven insights to identify root causes and recommend corrective actions.

Frequently Asked Questions

ModAE’s monitoring systems provide continuous oversight of critical machinery by tracking parameters such as vibration, temperature, and pressure. They help detect anomalies early, ensuring safe operations, reducing downtime, and improving overall equipment reliability in energy plants.

ModAE’s systems are designed with modular and scalable configurations, making integration with existing setups seamless. They support multiple communication protocols, enabling connectivity with diverse control systems and facilitating centralized monitoring of all critical equipment.

The systems provide early warning signals for equipment malfunctions, extend machinery lifespan, reduce maintenance costs, and enhance overall plant safety by enabling proactive maintenance and real-time performance monitoring.

Yes, ModAE’s monitoring systems are equipped with cloud-based platforms, allowing for remote access and control. This feature enables engineers to monitor machinery health and perform diagnostics from anywhere, ensuring continuous asset management without needing physical presence.

ModAE offers a range of support services, including installation, commissioning, lifecycle management, and remote diagnostics. These services ensure that monitoring systems perform optimally throughout their operational lifecycle, minimizing disruptions and maintaining high levels of reliability.